Knowing your plastic composition matters

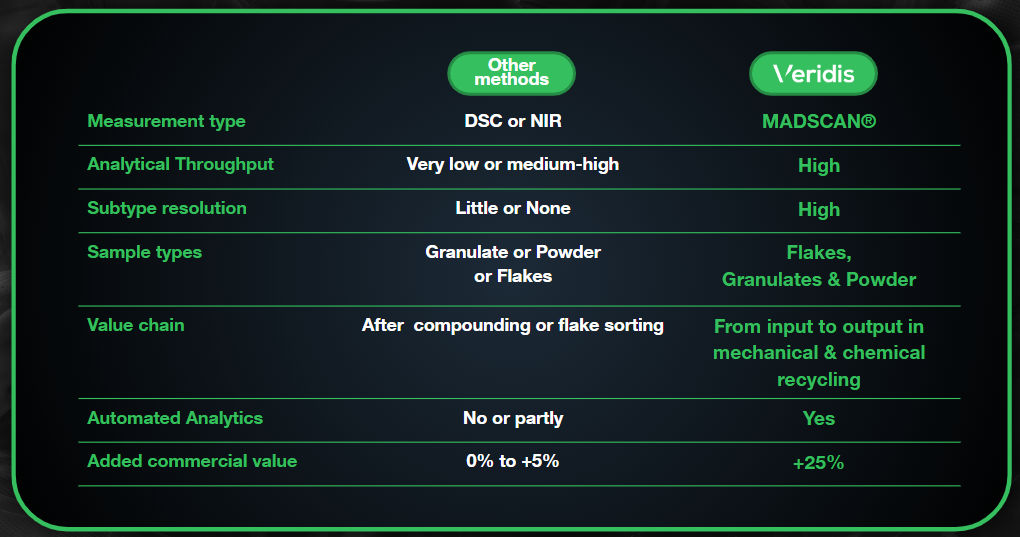

Veridis’ MADSCAN®, the first industrial-scale thermal analysis technology, giving >99% accurate insight into the composition of your complex plastic streams. MADSCAN®, enabling more profitable and efficient plastic recycling.

Mission & Vision

Veridis designs and develops industry-leading, innovative technologies for complex material characterisation, aiming to create a better future for humanity and the planet with a sustainable & circular economy.

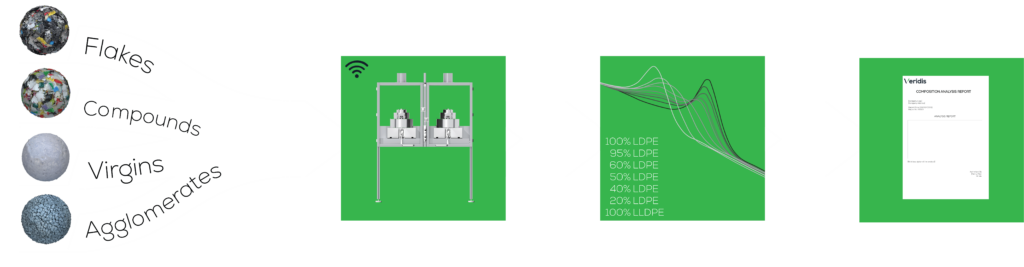

MADSCAN® Process

MADSCAN® transforms diverse plastic materials, from flakes, compounds, virgins and agglomerates, into actionable insights and certified quality assurance.

MADSCAN® Advantage

Request a MADSCAN® test

Get Accurate insights into PP, PE (HDPE/LDPE/LLDPE) fractions in your streams with Veridis’ T-30 MADSCAN.

Partners

Art Meets Sustainability: Waste Not, Create Art

Coming soon!!!

Upcoming Events & Recognition

15/10/2024. Exhibition

📍Beurs van Berlage, Amsterdam, The Netherlands

Come visit us!