INVESTMENTS SECURED FROM NETZSCH & DOEN PARTICIPATIES | COMPANY UPDATE

13-02-2024

Making recycled plastics the norm by 2030

Veridis secures funding from NETZSCH and DOEN Participaties to bring the new quality measurement standard (MADSCAN) to the market

13th of February 2024 – Eindhoven & Amsterdam. Investor NETZSCH and impact investor DOEN Participaties invest in Veridis to bring MADSCAN to the market. With its secured funding, in 2024 and 2025, Veridis will build and run customer pilots with its innovative MADSCAN technology. First in the Netherlands and Germany, having two of the most developed and well-connected plastic recycling industries in Europe. Then, the company will roll out its MADSCAN (eco)system across Europe, realizing its vision of a standardized quality control method for EU plastic recycling.

What is Veridis MADSCAN?

MADSCAN is a new thermal analysis technology, meaning that it measures the different ways in which different plastic types melt and crystallize again. Every type of plastic has a unique thermal ‘fingerprint’ and MADSCAN accurately measures these fingerprints by tracking these thermal changes when heating and cooling a sample of recycled plastic. This allows Veridis to tell recycling companies exactly which types of plastics are in their batches.

Jeroen Glansdorp, CEO Veridis:

“We are incredibly excited to have NETZSCH and DOEN Participaties on board to help us take our company and our technology MADSCAN into the next phase. Together, we are building the solution to accelerate plastic recycling!”

Why is Veridis MADSCAN so unique?

With conventional thermal analysis techniques, analyzing large, representative samples is impossible. This is due to the challenge of transferring heat equally through a larger amount of material. To illustrate, when a piece of frozen food, for example, chicken, is put in an oven, the outside will burn whilst the inside remains frozen. Heat does not transfer well throughout a large item. Because of this problem, today it’s only possible to measure samples of 20-50 milligrams at a time, which then needs to represent more than 1000 kilograms of material. This is of course not the case.

Veridis is the first company to solve this major challenge, being able to already analyze up to 30 grams per sample (a 10.000x sample size increase) today and between 50 and 500(!) grams per sample (a 100.000x sample size increase) with the MADSCAN system soon. This massive leap in scalability enables measuring the composition & quality of large amounts of recycled plastics at a representative scale. This allows recyclers to give better quality guarantees to brand owners to ensure that they can use recycled plastics reliably and effectively in their products to meet their ambitious recycling commitments.

The stakes are high!

25% recycled content in all our plastic packaging in 2027 in the Netherlands and 30% EU-wide in 2030, that’s the dot on our horizon according to the Packaging and Packaging Waste Directive (PPWD). Today, this still hovers around 2% because plastics are not all the same. There are 250+ types of plastics, but these can NOT be recycled together. Flexible food packaging (LDPE) and sturdy shampoo bottles (HDPE) end in the same (plastic)bin, but a Snickers wrapper and a bottle cannot be fused into a new bottle. But how do we measure how well we separate these millions of tons of yearly plastic waste? Barely, and that’s what Veridis aims to change.

It’s… complicated

Recycling plastic requires many complex steps to go from bin to new product. Knowing exactly what we’re recycling at each step is a challenge and existing control methods are not built to analyze plastics at the EU’s ambitious scales. Major brands have made big commitments and the EU dictates recycled contents minima. So we need to solve this challenge, fast!

The Veridis founding team: Founder Nigel Visser (left), CEO Jeroen Glansdorp (middle) & CTO Floris Gerritsen (right)

For more information and interview requests please contact +31 6 36143184

About Veridis

In the grand scheme of enhancing plastic recycling processes and comprehensive metrology for plastic recycling, this study serves as a reminder of the pivotal role of accurate measurement and characterisation. It underscores the necessity of standardised plastic waste characterisation and cooperation among stakeholders across the value chain, fostering a more circular and sustainable plastics economy.

About NETZSCH

Netzsch is one of the most prominent and experienced leaders in the high-precision measurement systems industry and will further cooperate with Veridis as a strategic investor to make its MADSCAN system fully industry-ready.

About DOEN Participaties

DOEN Participaties is the largest impact investor in sustainable and social startups in the Netherlands and has been investing in innovative, sustainable and social startups for more than 25 years. The organization has the ambition to make the world greener and more social. That is why impact is central to all investments. DOEN Participaties invests in the early phase of companies and dares to take risks. The company is fully owned and managed by the DOEN Foundation. The DOEN Foundation was set up by the Postcode Lottery. For more information see www.doenparticipaties.nl

Big brand with big commitments

/

RECYCLING QUALITY | RESEARCH HIGHLIGHT

05-11-23

Maximising Recyclate Quality in Plastic Processing: Insights from Compounding Companies

Accurate measurement and characterisation of plastic waste streams can improve plastic recycling processes, according to findings from a recent study.

Written by: Nigel Visser | Updated: 06/10/2023

Reviewed by: Floris Gerritsen | Published: 12/10/2023

The Study:

Quality Aspects in the Compounding of Plastic Recyclate

Where: Pforzheim University of Applied Science

When: Published January 31, 2023, in Recycling

The Takeaway:

Key findings from the survey reveal that the input material has minimal influence on the frequency of quality problems in a study conducted among compounding companies in Germany about the challenges they face in plastic reprocessing. However, component production is a more demanding step that immediately highlights quality problems. Using more test procedures to determine the material composition of the input material stream can reduce the frequency of quality problems. The research also suggests that online methods do not necessarily mitigate quality problems but increase the subjective perception of their frequency. The companies surveyed state that the causes of quality problems are found in the previous processing steps, such as sorting and collection. The study concludes that the mechanical processing of plastic waste into recyclates is currently the most frequent method used in Germany. Still, various problems can occur in the recycling process that may affect the final recyclate quality. The study is limited by the small dataset, which increases the uncertainty factor and the subjectivity of the respondents’ answers.

What It Looked At:

An examination took place into the processes and practices of compounding companies responsible for processing post-consumer plastic waste into high-quality recyclate material. Compounding companies were chosen because they play a critical role in ensuring that recycled plastic meets the required quality standards for new products.

Setting their sights on compounding companies, the researchers conducted interviews to understand their processes for sourcing, sorting, cleaning, and processing plastic waste. They also looked at the different technologies and equipment used by these companies to ensure the highest possible quality of the recycled plastic produced. Notably, the researchers analysed the various quality control measures employed by compounding companies to ensure that their recycled plastic is consistent and high quality.

Moreover, the study also considered the economic factors that affect the quality of recycled plastic. Compounding companies must balance the need for high-quality recyclate material with the cost of processing and the price they can obtain for the final product. The researchers explored how compounding companies optimise their processes to maximise the value of their products while maintaining high-quality standards.

In addition, the study also examined the compounding process used by several companies, including large and small-scale operations. It looked at the types of equipment used in the process, the quality of the raw materials used, the additives added to the plastic, and the process conditions (such as temperature and mixing time).

And finally, the researchers also examined the final product quality of the recyclate produced by these companies. They looked at the physical properties of the recycled plastic, such as its tensile strength and elongation, appearance, and colour. They also tested the recyclate for potential contaminants, such as residual monomers or other impurities that could affect the quality of the recycled material.

Overall, the study examined the complex processes and factors involved in maximising the quality of recycled plastic produced by compounding companies. By examining these factors, the researchers aimed to identify key lessons that could be applied to help other companies in the plastic processing industry improve the quality of their recycled plastic.

What It Found:

The authors of the article make a compelling case for the importance of accurate and standardised measurement and characterisation techniques for plastic waste, specifically in the context of recycling. The authors argue that the lack of standardised methods has led to inconsistencies in reporting and hindered progress in improving plastic recycling processes.

Furthermore, the article also highlights the limitations of current techniques and the need for further research to develop more efficient and reliable methods for measuring plastic waste. Additionally, the authors suggest that greater collaboration among researchers, policymakers, and industry stakeholders is necessary to address the challenges of plastic waste and promote sustainable solutions.

To sum it up, the article underscores the need for heightened precision, accuracy, and uniformity in measurement techniques. As well as greater collaboration and innovation to improve plastic recycling processes and mitigate the environmental impact of plastic waste.

Why It Matters:

In the grand scheme of enhancing plastic recycling processes and comprehensive metrology for plastic recycling, this study serves as a reminder of the pivotal role of accurate measurement and characterisation. It underscores the necessity of standardised plastic waste characterisation and cooperation among stakeholders across the value chain, fostering a more circular and sustainable plastics economy.

However, it’s essential to acknowledge the study’s focus on the mechanical properties of recycled plastic, omitting other vital factors such as chemical and thermal properties. The study’s limited use of only two types of plastics implies that the results may not be universally applicable. It also doesn’t explore the impact of diverse recycling processes on recycled plastic quality.

The following steps involve conducting broader research encompassing various plastics to validate the results across diverse materials. Examining the effect of different recycling processes on recycled plastic quality will further optimise recycling methods. Investigating the influence of recycled plastic age on its mechanical properties will provide insights into its suitability for specific applications.

Holistic metrology: Explainer

08-03-23

Measuring up to the challenge of plastic recycling: the importance of holistic metrology for circular plastics.

To move towards a circular economy, we need to increase the yield and quality of recycling processes. Adoption of a holistic metrology approach is essential to do this.

Written by: Nigel Visser | Updated: /03/2023

Reviewed by: Floris Gerritsen | Published: /03/2023

Holistic metrology is a method of measurement that takes into account the entire system and all of its variables rather than just one isolated aspect. In plastic recycling, this means looking at not just the composition of the plastic itself but also the conditions under which it is processed, the available technologies, and the end-use applications. By considering all of these factors together, it is possible to make more informed decisions about how to recycle plastic waste best.

Plastic waste is a major global concern and a pressing challenge for the sustainability of our planet. Despite numerous efforts to reduce the amount of plastic waste generated, it continues to accumulate in landfills, oceans, and ecosystems, causing widespread environmental damage. To tackle this problem and move towards a circular economy, where waste is reduced, reused, and recycled, we need to increase the yield and quality of recycling processes. To achieve this, a key aspect of the solution is the adoption of a holistic metrology approach.

Metrology is the science of measurement and its application in industry and commerce. By using precision measurements and instruments, it is possible to ensure that the recycling process is efficient, accurate, and sustainable. Holistic metrology takes this approach a step further, integrating all aspects of the recycling process into a comprehensive system that ensures the highest quality end product. This includes measurements of material properties, such as composition, size, and weight, as well as measurements of process parameters, such as temperature, pressure, and flow rate. By incorporating these measurements into a holistic approach, it is possible to optimise the recycling process and produce high-quality recycled plastic with minimal waste.

There are several key reasons why a holistic metrology approach is so important for plastic recycling. Firstly, it helps to ensure that the recycled plastic is high quality and suitable for its intended end-use. This is because by considering all of the variables, it is possible to identify and address any potential issues that impact the quality of the recycled material.

Another important benefit of holistic metrology is that it helps to optimise the recycling process itself. By considering the conditions under which the plastic is processed and the available technologies, it is possible to identify the most efficient and cost-effective methods for recycling. This, in turn, helps to reduce the costs of recycling and make the recycling process iselft a more sustainable and economically viable option. In addition to these benefits, holistic metrology also helps to support the development of new technologies and techniques for plastic recycling. By considering the entire system, it is possible to identify areas where improvements can be made and to explore new and innovative ways of recycling plastic waste.

There are several key applications of holistic metrology in plastic recycling, including:

- Composition Analysis is a fundamental aspect of holistic metrology in plastic recycling. By analysing the composition of plastic waste, it is possible to identify the type of plastic and its degree of degradation, contamination, or other impurities. This information is essential for selecting the appropriate recycling technology and processing conditions to achieve the desired properties in the recycled material. Holistic metrology can help to ensure the accurate and reliable measurement of composition, enabling better decision-making in the recycling process.

- Processing Conditions are another key aspect of holistic metrology in plastic recycling. By analysing the thermal properties of plastic waste, as enabled by thermal analysis methods, it is possible to identify the optimal processing conditions, including temperature, pressure, and residence time, to achieve the desired properties in the recycled material. This information can help to ensure a more efficient and effective recycling process, resulting in a higher yield of recycled plastic with minimal waste.

- Recycling Technologies are a critical aspect of holistic metrology in plastic recycling. By selecting the appropriate recycling technology for the type of plastic waste, it is possible to achieve a high level of precision and accuracy in the recycling process, resulting in a more efficient, sustainable, and cost-effective method of plastic recycling. Holistic metrology can help to identify the most suitable recycling technology based on the composition analysis and processing conditions, enabling a more effective recycling process.

- End-Use Applications are the ultimate goal of plastic recycling. By ensuring the quality of the recycled material, it is possible to create a valuable resource for the circular economy. Spectroscopy is an important application of holistic metrology in this regard, providing detailed information on the chemical composition and structure of plastic materials. By analysing the spectroscopic data, it is possible to identify the type of plastic and its degree of degradation, contamination, or other impurities, which can have a significant impact on the quality of the recycled material. This enables better decision-making in the recycling process and ensures the production of high-quality recycled plastic that meets the requirements of end-use applications.

The intended end-use of recycled plastic is also an important factor to consider in the recycling process. Holistic metrology takes into account the specific requirements of the end-use application, such as strength and durability, to ensure that the recycled plastic is suitable for its intended purpose.

Despite the many benefits of holistic metrology, several challenges must be overcome to realise its potential fully. One of the biggest challenges is the need for accurate and reliable measurement techniques. This requires the development of new and innovative technologies, as well as the investment in research and development to improve existing measurement methods.

Another challenge is the need for standardisation in the plastic recycling industry. With so many different types of plastic and so many variables to consider, it can be difficult to ensure that the same measurements are taken consistently across different recycling facilities. To address this issue, it is important to develop and implement standardised protocols for plastic recycling that are based on holistic metrology principles.

Finally, there is the challenge of making the results of holistic metrology more accessible and actionable. To maximise the benefits of this approach, it is important to develop tools and systems that can be used to collect and analyse data from different recycling facilities. This will allow the industry to identify best practices and to improve the quality and efficiency of plastic recycling continuously.

In conclusion, holistic metrology is an essential approach for plastic recycling that offers numerous benefits and provides a more comprehensive and accurate understanding of the recycling process. By taking into account all of the variables that impact the quality of the recycled material and the efficiency of the recycling process, it is possible to make more informed decisions and to improve the plastic recycling industry continuously. While there are challenges that must be overcome to realise the potential of holistic metrology fully, the benefits make it a critical component of any strategy to reduce plastic pollution and promote sustainability.

Green Alley Award ♻️

02-02-23

You can help us enabling scalable plastic recycling with 1 minute of your time! ♻️

We are excited to announce that Veridis is among the top 20 companies in the running for the Green Alley award 2023. After the initial application and selection, you can now help us by voting for Veridis at: https://lnkd.in/emCE5qfw before February 20th 23:59!

If we can reach the final, we’ll compete for the grand award and the cash investment that will be used for team expansions to improve our upcoming systems further and bring them to the market faster.

Your vote will help us a lot and be greatly appreciated!

Kicking off 2023! 🚀

30-01-23

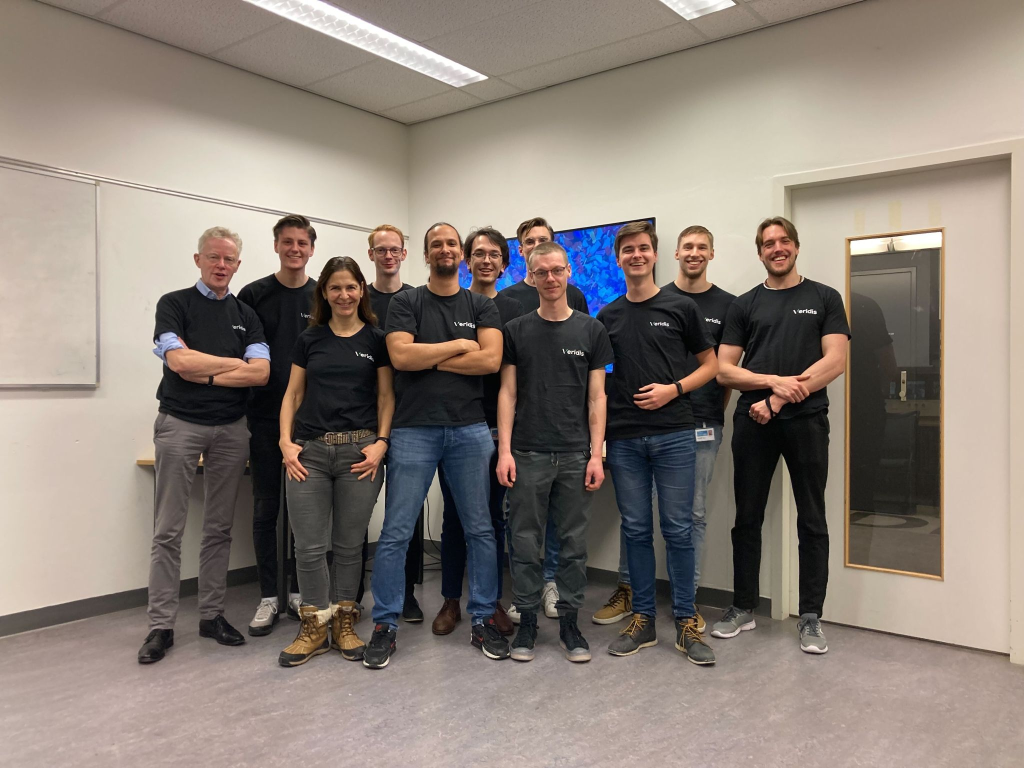

Last week, (nearly) the entire team of Veridis came together for our kick-off for 2023! We presented and discussed our journey thus far and what we will focus on in the new year, followed by a moment to bond as a team over some drinks and snacks. Seeing Veridis grow from a project started by four student founders to such a group of hard working, smart and exciting individuals gives us a lot of energy and motivation to do what we do and make the impact we want to make for the plastic recycling industry!

New Year!

17-01-23

New year, new steps towards a circular economy.

We hope you had a safe and enjoyable holiday season and are excited to start the new #circulareconomy year with you. Our top priority for this year is to contribute to the transition towards a circular plastics economy together with you. An essential aspect of this transition is polymer characterisation, and as we move forward, it becomes increasingly important to measure the quality of these materials accurately.

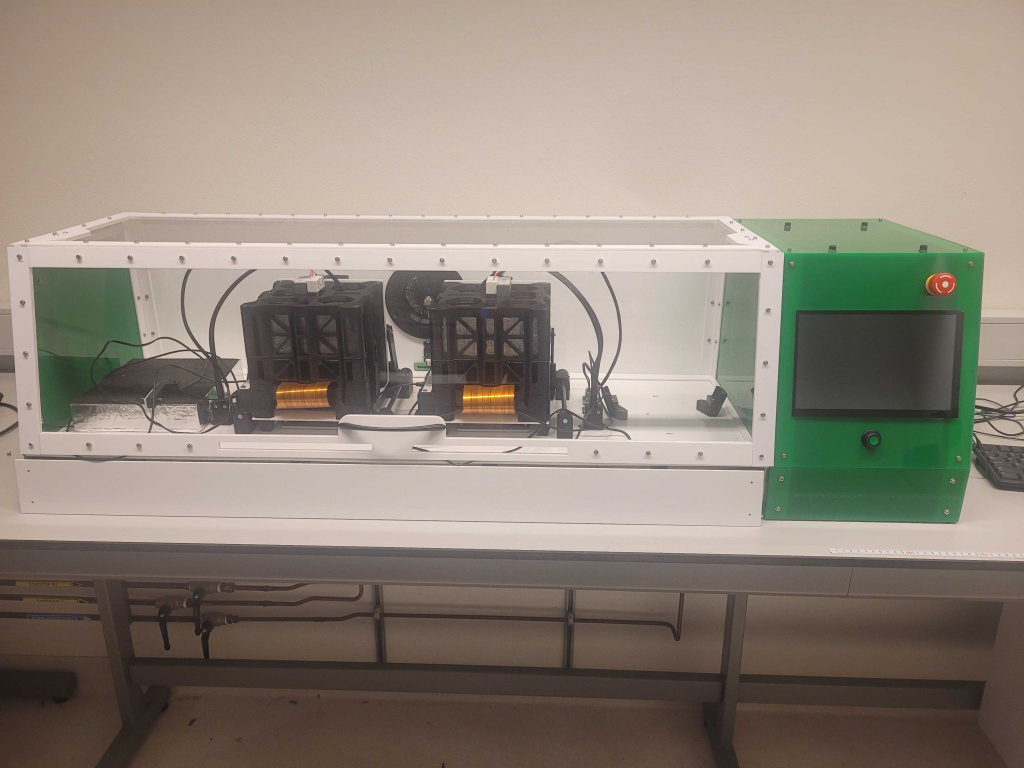

That’s where our MADSCAN systems come in. We’re proud to introduce our new MADSCAN T-30. This thermal analysis system can analyse samples at a statistically relevant scale, with the ability to measure up to 30 grams in a single measurement. The MADSCAN T-30 will be available for sample testing in the first quarter of the year.

In the photo, you can see our new system, which is currently undergoing extensive testing. If you’re interested in learning more about the MADSCAN T-30 or its release date, please don’t hesitate to sign up for our newsletter at veridis.tech or contact us at info@veridis.tech.

Eye-Openers

24-11-22

We are featured on the Eye-openers platform to explain our value in a short and clear format.

Circular chain project ♻️

07-10-22

We’ve kicked off our circular chain project to make the production process of the Rainblock even more sustainable.

Together with TUSTI BV., The Compound Company, Veridis, Water2keep BV and De Grondstoffendienst, we are building a closed circular chain wherein each partner brings their own experience and expertise. Due to the great motivation and openmindedness, everyone could feel the enthusiasm during our first physical meeting after the granting of a contribution by the Netherlands Enterprise Agency (RVO).

We have had our first ever Advisory Board meeting! ?

25-10-22

We have started holding our quarterly advisory board meetings to help tackle our greatest long-term challenges as a company. We see this as an important tool to make sure we are focussing on the right things and to make sure these are included in our company strategy. And this all happens through insightful discussions with our boardmembers.

Thank you Sven, Jurgen, and Ivo for your valuable insights!

We are looking for a Senior Business Developer!

04-10-22

We have an open position for an experienced business developer to scout market opportunities, define the market- and customer- propositions, and realise business deals. Your core job is developing new partnerships and potential customer relations across the waste-to-product value chain and validating product use case scenarios.

See more info at https://veridis.tech/jobs/. Send your motivation letter and curriculum vitae (CV) to Nigel Visser, CEO of Veridis, at ndjvisser@veridis.tech.

New demo at our next conference!

13-09-22

Visit our team tomorrow and Thursday at the Kunststoffenbeurs in the Brabanthallen in Den Bosch. Nigel Visser, Marie-José Wolters & Mathijs Kuil will be at our stand in Hall 2, stand 260B.

And with something special; we will demonstrate a model of our new setup! From November onwards, we will start commercially testing with our improved POC2 setup. This advancement of our MADSCAN technology allows us to measure more plastic types, at a larger sample size in less time than before. Curious to know more about the exact specifications or testing your plastics? Get in contact via info@veridis.tech or visit our stand at the Kunststoffenbeurs.

Looking forward to physically meeting you!

Internship alert!

30-08-22

This week Stijn van Aartsen is finishing his internship and as a part of this he presented his work last Thursday at the High Tech Campus Eindhoven. In his extensive study he developed an innovative method to analyse the MADSCAN data, providing more information on the polymer fractions and properties. A big step forward, thank you Stijn!

The main takeaway of the Plastic Recycling Show Europe is? Defining quality and how to measure it, is crucial for recycling plastics. ♻️

30-06-22

Seeing the openness and willingness to learn among the people at the Plastic Recycling Show Europe was great. However, one word missing in the conversations is an important one: The circular economy.

To reduce the pressure on the environment, tackle climate change and reduce dependence on fossil fuels, the transition towards a circular economy is crucial. The big challenge is on how to get there. Plastic recycling has a central role in this, and one of the essential things in this transition is recycling quality.

Figure 1

How is recycling quality currently defined?

There are nine keywords/phrases now being used regarding recycling quality:

| Keywords presently used to describe quality | Definitions |

| Impurity content | Is the content of untargeted materials or substances in a targeted waste stream. |

| Technical quality | Is a combination of the mechanical properties and the Melt-Flow Index (MFI) or a similar property which describes the molten plastics’ flow behaviour. |

| Technical properties | Are the properties that give the material the ability to function according to the required specification. Typically combines mechanical and processing characteristics. |

| Function/functionality/ functional recycling | Is a defined set of physical and chemical properties that made the material desirable in the first place – recycling them in such a way that preserves them. |

| Resource dissipation | Is the yield loss of material humanity can’t use anymore. |

| Substitutability | Is the degree to which a material is replaceable by an alternative resource or product (e.g. percentage of virgin plastics replaceable by recycled plastics without loss of function). |

| Circularity potential | Is how well a single recycling fraction can fulfil quality demands in a closed loop (e.g. how many cycles can the fraction go through before becoming unfit for purpose). |

| Downcycling / upcycling | A recycling process wherein a material is used in a product of lower market value instead of in a similar or higher market value product. |

| Closed-loop vs open-loop recycling | Closed-loop is a recycling process to reuse the recycled material for the same market application as in its previous life cycle. Open-loop means a different market application than the last cycle. |

The definitions all define pieces of quality for a recycling process, with some taking a system view and others looking more towards the material itself as well as the properties relevant for the production of products.

How do we properly define recycling quality?

Currently, recycling quality is a vague term. Everyone has a different interpretation due to the lack of a clear definition, as seen in the current variety of meanings. One of the causes is that what is good and bad quality is driven mainly by the use-case of the plastic. Thus a recyclate can be very well suited for one use-case/application and be unsuitable for another. This current measure of quality takes a single recycling loop into account. Yet, when going fully circular, the material will go through the loop several times and be less suitable to substitute virgin plastics. Hence, preserving the plastic’s functionality while considering the targeted application gives a good indication of the quality of a recycling process.

Figure 2: Quality seen through the lens of different waste treatment options [source].

How to measure recycling quality

The mechanical properties such as the elastic modulus in the transverse and machine direction, impact strength, and tear strength are important factors. And are very much dependent on the impurities that are present in the material. E.g., an HDPE/PP blend can quickly become brittle, dependent on the relative fraction of each polymer in the mix. In comparison, other PE types have a different mechanical profile in combination with PP.

Figure 3: Degree of mixing at the polymer blend interface: (a) compatible polymer blends with a mixed amorphous interface and (b) immiscible polymer blends with clear phase separation [source].

Determining the different subtypes and the fractions present is essential to properly determine the quality of plastic waste at various steps in the value chain, instead of only indicating the main polymer types (e.g. PE, PP) present in a stream. The amount of impurities defines the technical characteristics that give the material functionality for a specific application. By reliably measuring the quality, we know the process’s performance, enabling the opportunity to improve. Reliable quality and transparency depend on the data that players among the value chain share. Hence data reliability and transparency form the bedrock of a circular economy.

Conclusion

Recycling quality is currently already an important topic and will become more critical in the coming years as we go towards a circular economy as a society. As a topic, it deserves more attention, as a clear definition helps determine what goes well and what does not. This definition of recycling quality should take both the system and the material perspective into account within the boundaries of a circular economy.

Measuring quality means you can improve it. Taking a step toward a more data-driven recycling process means taking further steps toward Recycling 2.0 and a circular economy.

Nigel Visser

Visit us at the Plastics Recycling Show Europe!

09-06-22

In two weeks we will exhibit at the Plastics Recycling Show Europe in RAI Amsterdam. June 22nd & 23rd, we will showcase our MADSCAN technology at stand E72. We are providing a crucial step in the circularity of plastics through the identification and analysis of high quality, recycled materials. Have a look at this link for more information or visit stand E72.

Final of the Philips Innovation Award today!

30-05-22

We are super excited to be part of the final of the Philips Innovation Award. See Nigel Visser & Mathijs Kuil explain in the short movie why we need to win! Tune in via the live stream at 19:30 to see Mathijs Kuil pitch: https://lnkd.in/grciNeYt.

Special lab visit

22-04-22

Yesterday, Martijn van Gruijthuijsen, deputy of the Provincie Noord-Brabant, visited our lab to sneak peak our technology. Together with Gerard Spanbroek from Brabant Startup Fonds, we will work towards enabling recycling 2.0.

The MADSCAN technology provides a crucial step in the circularity of plastics through the identification and analysis of high quality, recycled materials.

Global recycling day

18-03-22

Plastic recycling is facing big challenges, which require new innovative solutions. Earlier this month, 175 nations signed the historic UN resolution in Nairobi to ‘end the global scourge of plastic pollution’. This resolution will lead to large challenges in recycling. With Veridis we aim to offer a solution for these challenges, through a new analysis for high-quality plastic recycling.

Another internship finished!

17-03-22

Last week, Tom Willaert gave his final presentation. With this background in Applied Physics, he worked on improving our signal analysis. Tom also worked on a new model for the optimisation for yield and quality in sorting facilities through the MADSCAN technology. Good luck, Tom!

Would you like to be part of the team that is redefining plastic recycling and accelerating the shift to a circular economy? We are developing an innovative thermal analysis for the characterization of recycled plastics. We have various open internship positions in the field of data analytics, thermal simulation and electrical & mechanical engineering. Take a look at https://veridis.tech/jobs/ or send your CV + motivation to info@veridis.tech.

ExtremeTechChallenge Netherlands & Belgium finalist!

04-03-22

We are very happy to announce that Veridis has been selected as a finalist of the Extreme Tech Challenge Netherlands & Belgium!

We will deliver our amazing pitch on the 24th of March at the High Tech Campus Eindhoven. Also, a well deserved congratulations to the other startups in the HighTechXL family on reaching the final!

Philips Innovation Award Semi-Finalist!

01-03-22

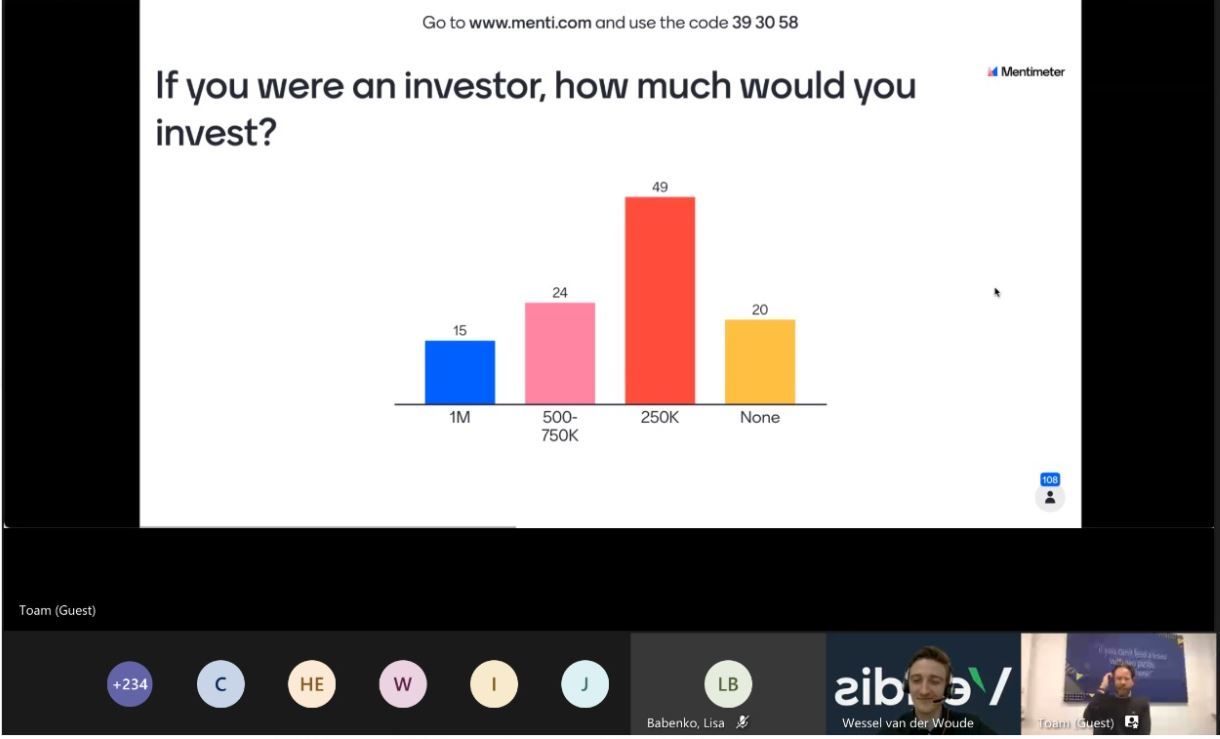

We are proud to be chosen as Semi-Finalist of the Philips Innovation Award. On Thursday, Mathijs Kuil & Wessel van der Woude visited the Investor Day at YES!Delft. 1st of April there will be a live pitch to become a finalist.

Internship finished

20-10-22

Today, Pepijn Kruidenier finished his Data Generation and AI internship with us. With his final presentation he showed the application of GANs and Cycle GANs to improve the MADSCAN technology. A big thanks to Pepijn!

Would you like to be part of the team that is redefining plastic recycling and accelerating the shift to a circular economy? We are developing a novel thermal analysis for the characterization of materials. We have various open internship positions in the field of data analytics, thermal simulation and electrical & mechanical engineering. Take a look at https://veridis.tech/jobs/ or send your CV + motivation to info@veridis.tech

A new Veridis milestone

10-02-22

Just before the end of 2021: we detected a 1% impurity in a plastic mix of 2 grams using the proof of concept of our MADSCAN technology. Through daily testing on different plastic samples, we were able to improve our data analysis. This means we are ready for the first commercial tests with the MADSCAN!

If you are looking for commercial testing on large plastic samples, inquire via info@veridis.tech. We are able to measure small impurities on 2 grams samples for different plastic types. Small impurities in plastic samples are crucial for optimized and efficient plastic recycling streams. Our technology leads to more and accurate information for industrial samples in plastic recycling

Meet us today and tomorrow on the PRSE 2021

04-11-21

Nigel Visser, Marie-José Wolters, Mathijs Kuil, Floris Gerritsen & Wessel van der Woude will be at the PRSE 2021 in the RAI Amsterdam.

Come talk to us about our MADSCAN. We are providing a crucial step in the circularity of plastics through the identification and analysis of high quality, recycled materials.

Not one, but two nominations!

28-09-21

Out of 4000+ applications, we are selected as Deep Tech Pioneer by Hello Tomorrow! We are recognized as one of the most promising deep tech projects to date. The nomination gives us the opportunity to engage at the biggest deep tech event, the Hello Tomorrow Global Summit 2 and 3 December.

But that is not enough; ASN Bank also selected us for their Wereldprijs 2021! This makes us part of the top 30 initiatives in the Netherlands working on a better future. Great to participate with other Dutch impact entrepreneurs.

We have won the ING Circulair Entrepreneurship Price!

07-09-21

We are super proud to tell that we have won! Yesterday, Nigel Visser received the award on Duurzame Dinsdag. Great to see our mission to revolutionize plastic recycling is recognized and supported. With the identification and analysis of high quality, recycled materials we are providing a crucial step in the circularity of plastics.

Also, ING made a nice article about us, our technology and why we want to revolutionize plastic recycling. You can find the article by clicking here.

Product milestone hit

24-08-21

We have measured & identified a plastic mix of 2 grams within a 95% accuracy. With this milestone, we have shown a 100x improvement in sample size in comparison to what is currently possible in the plastic recycling market. We have performed the thermal analysis on a sample mix of HDPE & PP.

From this milestone onwards, we will gradually improve our technology. Our fully developed MADSCAN technology will measure 500 grams with a 99% accuracy, a 100.000x improvement. Besides sample tests, we are also performing tests on materials from our plastic recycling partners. Our technology leads to more and accurate information on an industrial relevant sample size for plastic.

IPCC report

17-08-21

Do you want to work on a solution tackling climate change ❓

There is ‘high confidence’ that the recent growth in emissions is driven by waste management according the new IPCC report. In earlier reports, the energy-intensive production processes of plastic were already identified as main causes of climate change. Recycling is the solution replacing these energy-intensive production processes in plastic.

The recent IPCC report increases the need to tackle climate change. At Veridis, we use science & technology to solve one of the main causes. Our MADSCAN technology is a crucial step in the availability of recycled plastics. It allows quality control for the highest quality at sufficient quantity in recycled materials.

Want to work on future solution tackling climate change? We have a new open internship in our Business Development team. Send your CV & list of grades to info@veridis.tech, or take a look at: https://lnkd.in/dqMD2rYK

Do you want to be amongst the first group of pilot testers? Contact our team directly via info@veridis.tech or inquire via this website.

Pitch @ XL Day

16-07-21

Last week our CBO Wessel gave our pitch at the first big live event since we have joined the HighTechXL program. And he did an amazing job! ?

This was a spectacular way to finish the nine month program and we can’t wait to show you what comes next! Click here to see more details from the event provided by Dispatches Europe.

We want to thank the whole HighTechXL team for their support, and especially Robin van Scheijndel, Toam Jaber, Eddy Allefs & Tim Heijwegen for their close weekly support.

HighTechXL’s XL Day

10-07-21

See us live at HighTechXL’s XL DAY at July 16th! ⏰

After nine months of hard and rewarding work, we are nearing the end of the HighTechXL venture building program. As one of their “Covid Cohorts” we will be pitching our company in front of many investors, multinationals, experts and more. The event will be both online and in-person. It will be our first pitch on stage for such a big audience and we can’t wait!

TSE Industry finished

09-07-21

We have successfully conducted the TopSector Energy Industry (TSE Industry) subsidy research focused on further research into the analysis of recycled plastics and system specific research questions. We are very grateful for the governmental support in our journey to help plastic recycling take the next step.

Pitch @ Innovative and Sustainable Packaging Event

11-06-21

Pitch, pitch, pitch ?️

Yesterday, we presented at the Innovative and Sustainable Packaging Event from Kennisinstituut Duurzaam Verpakken (KIDV). As innovator in plastic recycling, we discussed our technology with experts from the packaging industry. Also great to hear from experts like Martine Brandsma from Nationaal Testcentrum Circulaire Plastics on how to tackle the problems in plastic packaging.

Our MADSCAN technology is a crucial step in the availability of recycled plastics in packaging. It allows quality control for the highest quality at sufficient quantity in recycled materials.

Sustainable Young 100

27-05-21

Our CEO Nigel Visser has been selected as one of the 200 nominees for the Sustainable Young 100. Please vote here and got Nigel and Veridis to the Nr. 1 spot!

Successfully finished phase 2 of HighTechXL

21-05-21

We keep on going and growing ?

We are through to phase 3 of HighTechXL‘s Venture Building program. This means we keep on working towards the revolution in plastic recycling with the help of the great people at HighTechXL. During the program, we were able to grow the team and venture for our Minimum Viable Product.

Showcase at the Hannover Messe

12-04-21

This week, we will showcase at the Hannover Messe!

The world’s leading trade fair for industrial technology. Our CEO Nigel Visser will showcase how we approach the revolution in plastic recycling. Our innovative quality control for plastic recycling fits with improved industrial standards for recycled plastics.

Finalist Alliance to End Plastic Waste

07-04-21

We are proud to be chosen as one of the 11 startups to join the Alliance to End Plastic Waste!

The Alliance to End Plastic Waste entails 50 multinationals, with the common goal to reduce plastic waste. Our innovative technology was recognized to do just that, and we are excited to join this movement. Through the End Plastic Waste platform, we can showcase our innovative technology and accelerate towards a circular plastics economy.

Completed phase 1 of HighTechXL

02-02-21

We have completed Phase 1 of HighTechXL‘s Venture Building Program ✔️.

Together with their help, we have built a strong foundation for analysis in plastic recycling. Now, we will move forward and continue developing through phase 2.

Successful pitch at XL-Day

15-01-21

We pitched at HighTechXL‘s XL-Day. It was a great opportunity and experience to pitch in front of more than 200 people including many investors and potential partners. And, even more important, the audience was convinced that plastic recycling could be improved drastically with our solution.

Veridis receives subsidy

15-10-20

We have received a subsidy of €70.000 through the TopSector Energy Industry (TSE Industry) for further research into the analysis of recycled plastics. ?

Veridis joins HighTechXL

5-10-20

We are very happy to announce we have officially joined the high tech startup accelerator HighTechXL, part of the International Top Five List of Startup Accelerators by Perceptionbox. In this 9 month program we will develop all the aspect of our business and product as well as receive many opportunities to pitch to investors and interesting parties.

Recognition

17-08-20

We were mentioned by the the President of the Vrije Universiteit Amsterdam Mirjam van Praag in an interview about the energy transition: amsterdameconomicboard.com/nieuws/de-energietransitie-bestaat-uit-heel-veel-deeloplossingen

Veridis Incorporated

10-07-20

On 10-07-20 Veridis was officially incorporated in Amsterdam with the help of Notariskantoor Van Zaane. ?

First results

17-05-20

For the first time since the initial idea for a scaled up DSC, we have identified the plastic melting peak of HDPE using a two grams proof of concept version of our envisioned product.